Travis Dormer

Have you noticed that better drill site environmental practices are accelerating faster than ever?

At a Glance

Particularly when it comes to the use of plastic products on our drill programs.

The two biggest plastic consumables drill programs have are:

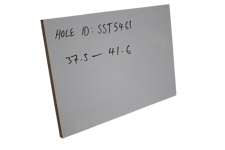

- Plastic Core Trays

- Plastic Sample Bags

Until now, using a biodegradable & compostable plastic bag has been dismissed or never pursued.

Likewise using recycled polymer (kerbside plastic) in our plastic core trays has never been pursued.

Ok, so what is possible?

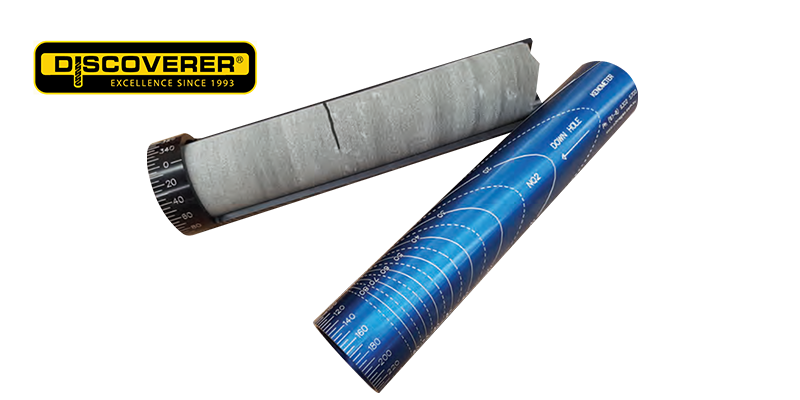

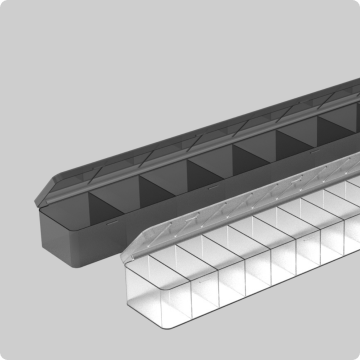

Let's begin with the core trays.

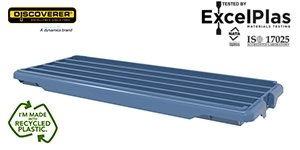

Here in Australia, Dynamics G-Ex decided to partner with specialist recyclers to find a way to make use of Australian kerbside plastic.

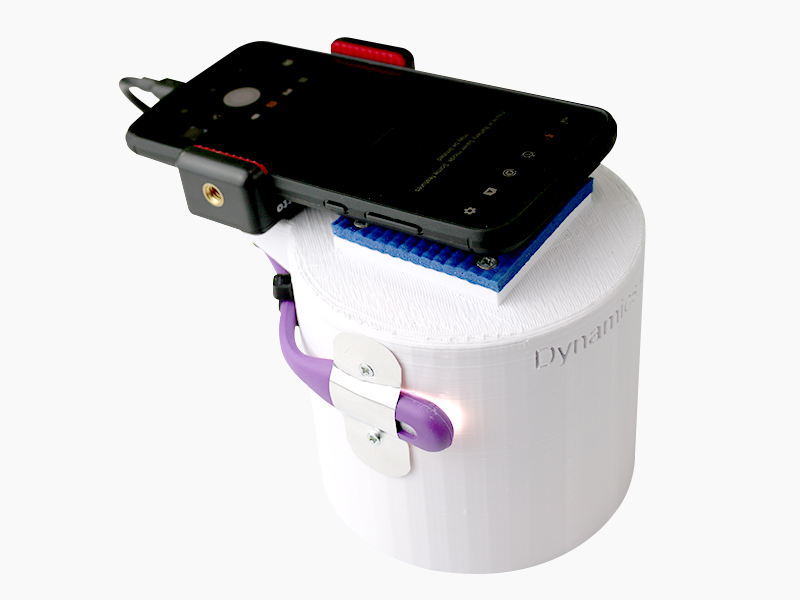

New innovation using state-of-the-art technology to purify the recycled plastic means for the first time ever, the plastics you put in your recycle bin at home has been reused to create a Discoverer Core Tray.

Interesting or boring?

Maybe it only becomes interesting when we realise the extent of the problem Australia faces.

For years, Australia has been shipping our plastic waste to China.

Long story short - they no longer want it.

The Government are left to sort our own plastic waste and the recycling industry is hopelessly behind with it.

With miners and explorers under increasing pressure and delayed approvals through their various environmental impacts, we must find good Corporate Social Responsibility stories.

Dynamics are trying to find simple but practical ways for you to show your shareholders that you are aware and you care.

Whether you are an avid Circular Economy fan or it's the last thing on your mind, one thing is starting to happen:

"Miners and Explorers shareholders, and sometimes the balance of shareholders, are starting to force environmental changes to our longstanding practices."

Read this article from Rio Tinto:

https://www.australianmining.com.au/news/rio-tinto-introduces-new-role-for-future-strategy/

At a strategic level they are committed to aligning their 'business with shareholders’ social and environmental priorities.'

It will filter down to every junior explorer soon enough.

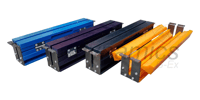

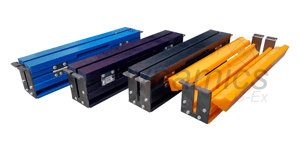

Core Trays - Virgin v Recycled Challenge

For years, only virgin material was good enough for plastic core trays, and that's what we've always used.

Now new technologies are able to sort kerbside plastic into its different polymers and remove crucial impurities (e.g. oily substances).

Until now, it wasn’t possible to use recycled polymer effectively and that's why only virgin polymer was used.

With the right technologies, this recycled polymer is now just as robust as virgin.

Using recycled plastics in commercial & everyday products isn't something new either, for a number of years children's playgrounds have been made for recycled plastic.

Check out these sources:

https://www.playgroundequipment.com/turning-used-plastic-containers-into-playgrounds-for-children/ https://srpplayground.com/recycled-playground-equipment

If probably the world's most regulated industry, especially when it involves small children, feel recycled plastic passes the test of time, that leaves little reason for us to be concerned.

To remove all doubt, all the Discoverer Trays we produce have been tried, tested & proven by NATA and ISO Certified Plastics Lab ExcelPlas. Following a robust QC Testing Process, Discoverer® is the only Core Tray on the global market that has undergone this rigorous independent testing.

In some circumstances, ‘environmentally-friendly’ options have been seen as inferior.

In 2019, maybe this was true.

2020 - different story.

Technology to achieve this will never slow down, it just becomes a matter of keeping up.

Plastic Sample Bags - The Proverbial Problem!

Green UV plastic bags are expected to hold samples for a relatively short period of time.

The problem is that virgin Green UV plastic bags take 25+ years to break down fully.

That's why collecting, emptying and disposing of all plastic sample bags after a drill program is a requirement.

If left behind, they break down into microplastics that damage the environment.

Fundamentally, Green UV bags are designed to be ‘tough’.

- Puncture/tear resistant

- Seams that don’t burst

- UV stable to last in the harsh sun

So the question for the industry became:

How do we get an environmental alternative

with the same properties,

without the need to send a field team to collect all plastic so the rehabilitation process could begin?

This really is a waste of time and money on ‘unproductive’ man hours.

We do this currently as it is what we are legally required to do.

The Regulations

Here are a couple of Government Exploration regulation extracts:

VIC

Samples should be moved off site on a daily or weekly basis or within the shortest possible timeframe. On Crown land, samples may be retained on site for up to four weeks from completion of the program with the Crown land manager’s agreement.

WA

Tenement holders are required to remove all waste materials, rubbish, plastic sample bags etc. from the tenement prior to or at the termination of the exploration program (abbreviated version from the below source).

Source: http://www.dmp.wa.gov.au/Documents/Minerals/Minerals-AdminOperation_Sep2013.pdf

So what are the options?

There's a couple:

- Stick with your existing Green UV bags, it's worked for years.

- Use a biodegradable & compostable green bag.

Regardless of what you decide to do now, there are major government-driven changes to be aware of.

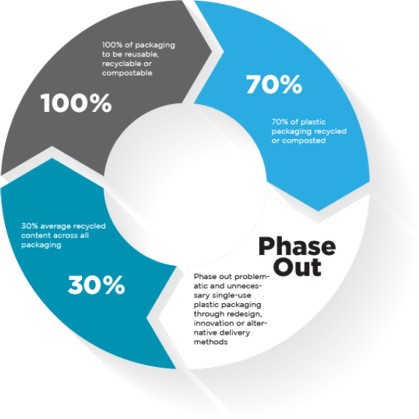

Here's Australia's 2025 Targets in relation to plastics:

I'm not sure if the entire industry is ready for this...

A biodegradable & compostable bag, right now, is 2.5 times the price.

Circa $2 each for 600x900mm bag.

However, the faster this change is embraced, economies of scale will factor in to reduce this price.

For others, we might be dragged kicking and screaming into the change.

In a nutshell, to meet new government regulations we need to start thinking about this.

On a positive note, relationships with pastoralists will improve.

Burying your bags in the sump, in an environment-friendly way, while reducing your labour cost may be a massive bonus?

Don't get deceived by the general 'biodegradable' terminology.

The differences are explained in this article, and you can find out what you can trust!

Dynamics G-Ex believe mining can change its ‘dirty’ industry image, that we believe at times is unfairly attributed.

It just takes a few of us to jump onboard.

.png)