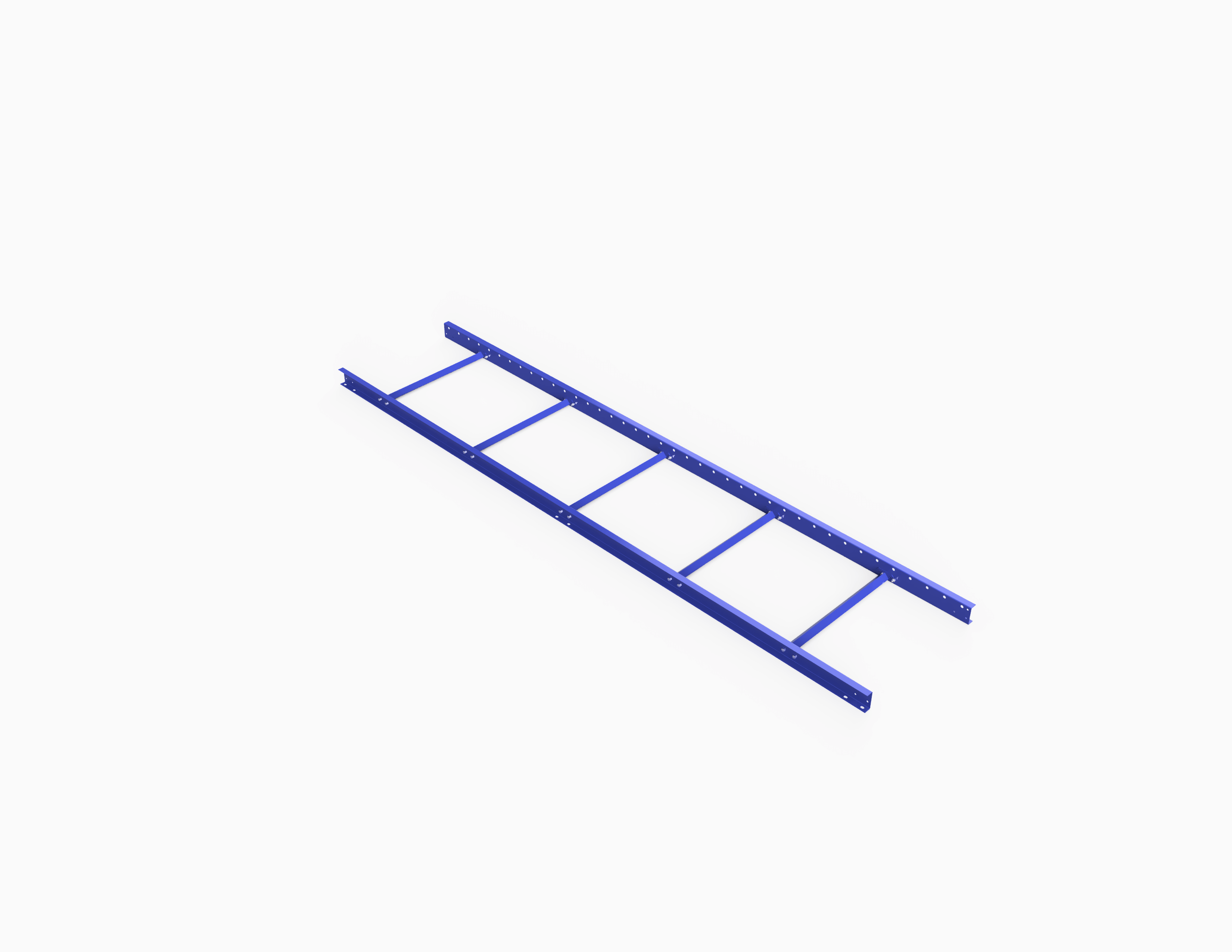

We stock a wide range of gravity roller table conveyors to suit any core shed application and have designed many systems to meet your exact requirements, specializing solely in Core Shed Design, using standard stock roller racking parts for many years.

Step 1. Send Specs

Send us your shed drawing, a sketch with measurements or professional drawing; either is fine.

Step 2. Complimentary Design

We will professionally draw up your entire shed layout, working with your needs and using our extensive experience of the many core shed applications we've completed. Simple concept design layout shown left and below.

Dynamics Designed, Manufactured & Supplied Core Shed

Step 3. Sign Off

Sign off on the drawing, finalise the quote, and place your order. Generally we stock standard components, so can have your lean and efficient new core shed up and running within a matter of 1-2 weeks. Large or customer projects may be subject to a longer lead time, and will be advised at time of order.

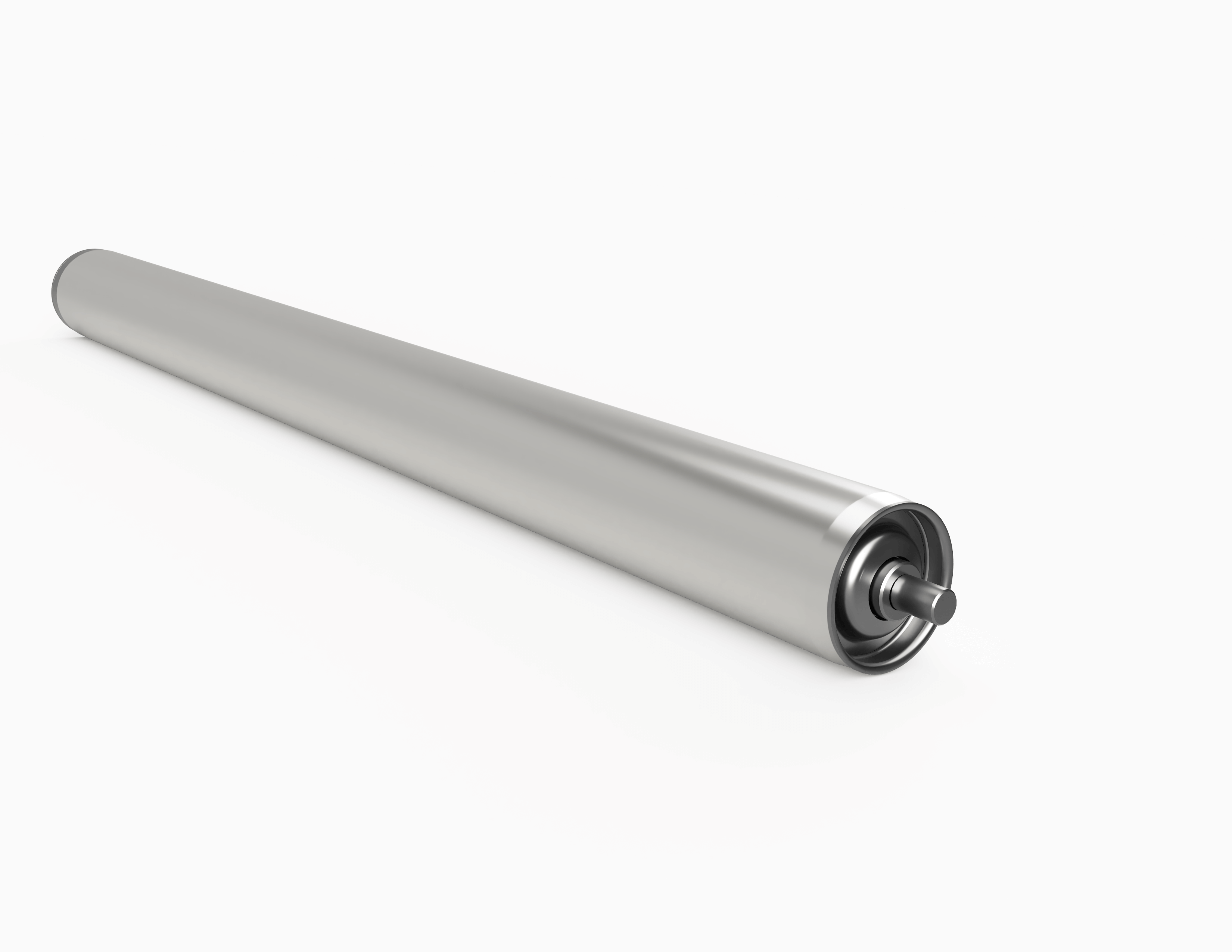

FAQ: How many rollers do you need per metre?

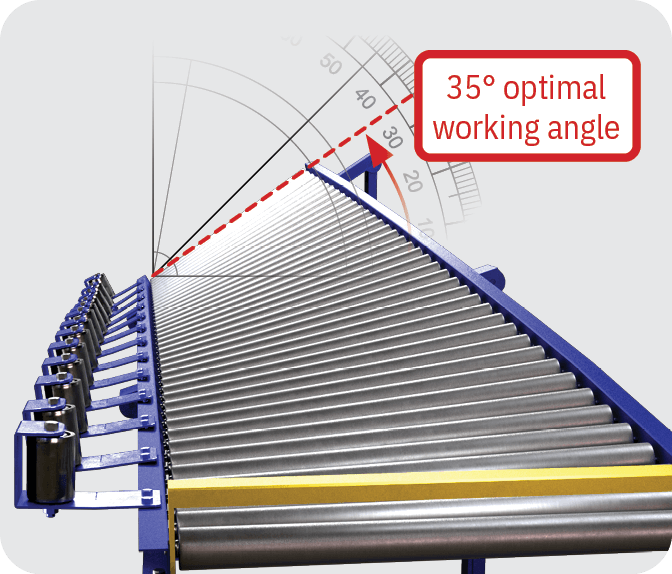

As standard we suggest putting rollers every 75mm; however, it’s largely dependent on which way you log the core and move the trays along. If the trays are only going to be logged and moved along parallel with racking then you can 'get away with' putting the rollers at 150mm centres. If you plan on moving the trays “sideways” along the racking (long side of the tray leading), then it’s recommended that you have the rollers at 75mm. Additional rollers can be easily retrofitted.

FAQ: How many support legs do you need per section?

We suggest at every 3m straight section join when the trays will be moved parallel with the racks. However if you plan on moving trays sideways, due to the weight per metre of rack, it's highly recommended to have an additional support leg in the centre of every 3m section.

See our blog on How to achieve a world-class core shed workflow within the most basic of facilities

--------------------------

For customers keen to plan out what's possible if their core shed, you may find a list of standard components below. Typically our most popular core shed size is the 600mm width rollers, as this offers the flexibility to run your core trays lengthways or sideways without becoming a WHS risk. However, if the budget is tight and you'd like to look at the 400mm option, you can expect this system to typically cost between 5-10% less than 600mm system.

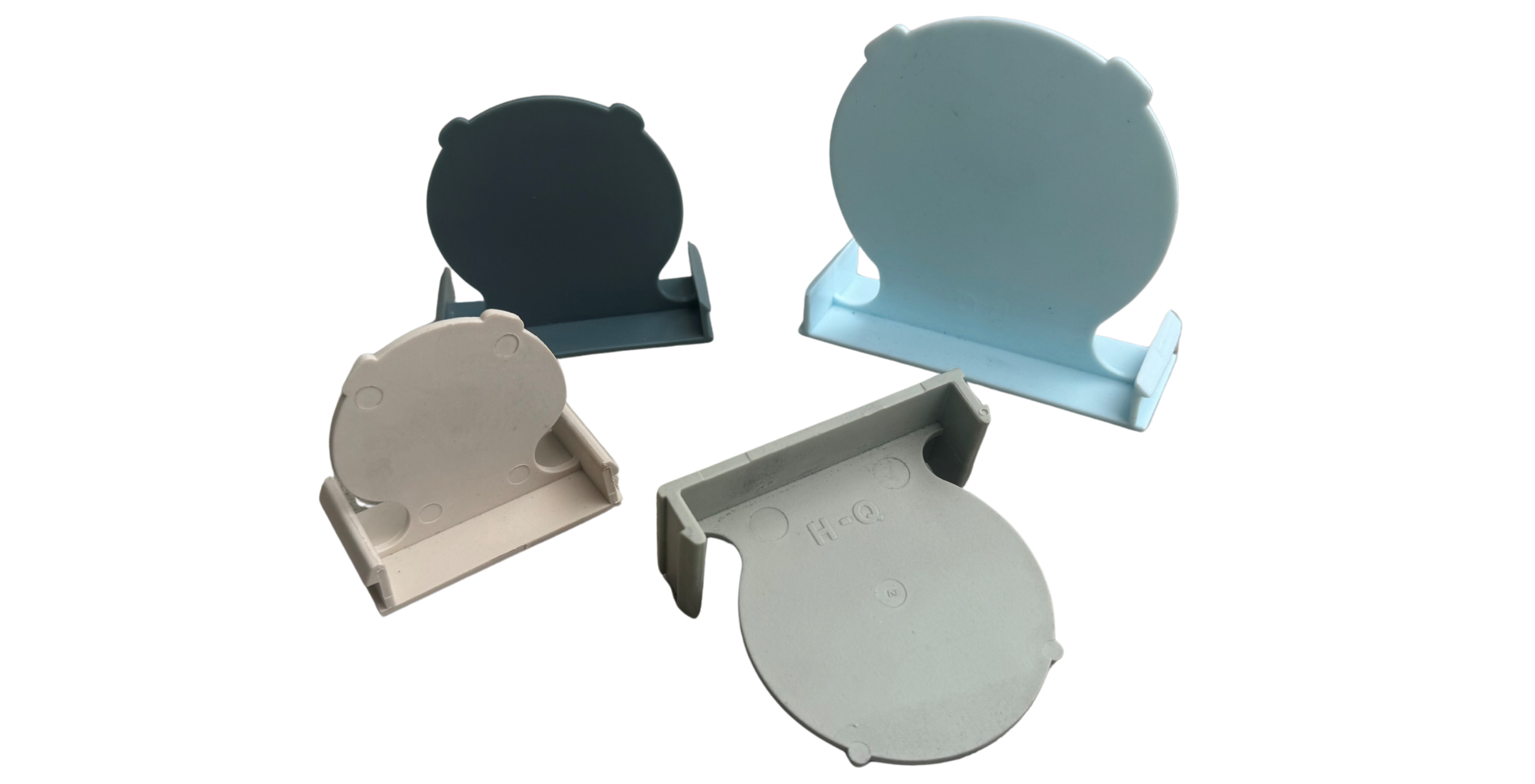

Have you seen the Latest Fixed Camera Frame? It's designed for bolting to Roller Racking as a permanent fixture. Click on the image for more details.