Spencer Dormer

Rocket Launcher... Nope, we aren't going into nuclear warfare!

This core orientation device has probably adopted this name due to how it looks.

Essentially, it's a portable wooden frame that enables a piece of core to be set up in the same orientation as it was when part of mother earth.

From there, structures can be measured with a geologist’s compass in the usual way.

The two ways of measuring structures in oriented drill core

Let's start with the rocket launcher.

Set up the core in a core frame so that it lies in the same orientation as it did when it was in the ground.

The structures within the core are then measured using a compass, just as a structure exposed in a surface outcrop would be measured.

The second way is to use a protractor to measure the angles that the structure makes with lines and planes of known orientation (the core axis, the bottom-of-hole orientation line).

The angles can then be used to calculate the strike and dip (if planar) or the trend and plunge (if linear) of the structure.

This is known as the internal core angles method.

The Rocket or the Protractor – which is the better device?

For most drill core orientation applications, it is recommended that a core frame be used to measure the structures.

Core frames are a cost-effective, low-tech and readily available tool.

The frame permits direct visualisation of structures in their original orientation, allowing them to have 'real time' geological meaning.

Setting up core in a frame permits not only measurement of individual structures but, more importantly, allows the relationships between sets of structures in the same piece of core to be observed.

Measurements can be constantly compared against the evolving geological model for the deposit as the core is being logged.

Significant changes in attitude of structures can be identified and examined in more detail while the core is still laid out.

Mistakes in measurement (or problems with the core orientation line) can be quickly spotted.

In short:

Core orientation frames are GEOLOGIST- FRIENDLY.

Even where the internal core angles method is being used, a core frame must also be available in order to measure planes with high alpha angles[1].

In addition, a core frame is the only way in which non-penetrative linear structures, such as fold axes, can be measured.

For most applications in logging core, the use of a core frame is recommended.

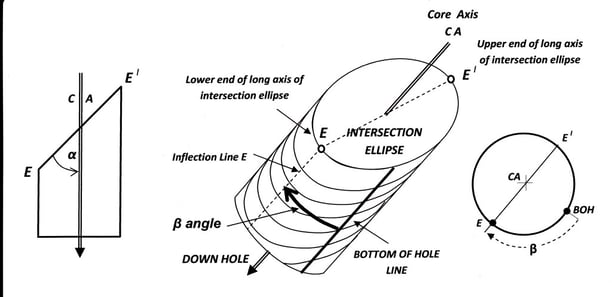

The internal core angle technique involves measuring two angles referred to as alpha and beta.

These two numbers (meaningless on their own) are then fed into a computer where they are crunched with down-hole survey data to produce the attitude of the measured structure in terms of a standard dip and dip direction measurement.

This number processing can also be done manually using a stereonet.

You can find full details in “Geological methods in mineral exploration and mining” (Springer 2011).

Definition of the angles that a planar structure makes with the core axis (CA) and the bottom-of-hole (BOH) lines in surveyed and oriented diamond drill core.

The alpha angle is the acute angle between core axis (CA) and the line E-E (the long axis of the intersection ellipse).

The beta angle is the angle between the bottom-of-hole (BOH) line and E.

This is measured around the core circumference in a clockwise direction when looking down the hole. The beta angle can range from 0 to 359 degrees.

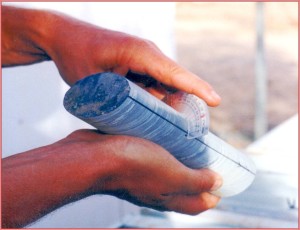

Using a simple home-made protractor to measure the alpha angle of a planar structure in a piece of oriented drill core.

Measuring the beta angle of a planar structure in a piece of oriented drill core.

The black line marks the bottom-of-hole (BOH); it represents the intersection of the original vertical plane with the core and has been determined by a special down-hole core orientation survey procedure.

The protractor is a basic school plastic 180 degree model ($2.80 at any good stationer or newsagent) cut to fit the core circumference.

More elaborate beta-angle protractors are sold commercially, but none are as accurate or as easy to use as this design.

The alpha-beta method was developed in 1979 by the geotechnical engineer R E Goodman.

It means rapidly taking a large number of measurements that could be plotted in bulk and analysed statistically.

Statistical handling of bulk plots has value in geotechnical studies but tends to obscure geological relationships by promoting quantity over quality.

Nevertheless, the speed and ease of making alpha/beta measurements as digital computer feed, and the fact that it is a mechanical, mindless process which obviates the geologist from actually having to think about the meaning of what he or she is actually looking at, has made the technique very popular.

It is fair to say that in most drilling programs using oriented core, the alpha-beta method is now the technique of choice from the very first exploration hole through to final ore definition drilling.

The reality is that the transfer of this technique from the geotechnical engineering field to the structural geology field has been, with few exceptions, a disaster for geological understanding.

It encourages a culture of filling data bases with thousands of meaningless numbers in the hope (seldom fulfilled) that somewhere there is a computer program that will tell the geologist what it all means.

Geologists should always resist being turned from professionals whose brains are actively engaged with the material they are examining into mere operatives and collectors of endless numbers to be entered into computer data bases.

Lest I be thought biased, I must point out that the internal core angles method of measuring planar structure in core does offer some advantages over using a core frame:

-

Measuring alpha/beta angles is much faster than using a core frame.

-

If the requirement is to make a very large number of measurements of a set of planar structures, whose identification and significance are otherwise well understood, with a view to a statistical treatment of the results, then the internal core angle technique, with computer processing of the results, provides the quickest and most effective option.

This situation can arise, for example, in a mine application, in geotechnical logging or in the advanced infill drilling stages of prospect exploration.

In this case, the internal angles would normally be entered directly onto a spread sheet type of log form (or directly into a portable computer) for subsequent processing.

Presentation will usually be in the form of a computer generated section or map, a stereonet pole figure or a histogram.

However, even for these applications, the inherent limitations (often impossibility) on the use of this method, for planes with particular orientations, or for measuring non-planar structure, need to be borne in mind.

-

Measuring internal core angles may be the most efficient method of recording structure attitude onto analytical spread-sheet type logs during the advanced drilling stages of a prospect.

[1] As alpha angles increase, the ability to measure an accurate beta angle decreases. The relationship is not linear but exponential.

Specifying a cut-off point for use of the method depends on particular circumstances (how planar the structure, how well defined, how penetrative etc.). But, in general, for all alphas over 65°, the inability to measure an accurate beta becomes too great to allow meaningful calculation of dip and dip direction.

Few geologists using the internal angles method are aware of this, and inaccurate beta measurement are routinely entered into databases, creating a significant GIGO effect for any subsequent computer processed output.

Source: Roger Marjoribanks

A large portion of this article is written by the original inventor:

Roger Marjoribanks, BSc PhD FSEG FAIG

Consultant in structural & economic geology

Roger used to manufacture and supply the Marjex Core Orientation Frames, but he no longer does.

You'll find his website directs you back to Dynamics for supply.

Although we've adapted the core orientation device from the original, you may still download the operating instructions here:

Core Orientation Device Operating Instructions

We also found this Core Orientation Standard Procedure.

This is written by Daniel Apau, working at Golden Star Exploration. It's public on Research Gate.

For further reading, you may also find this useful: Orefind.com

Have any more questions about drill core orientation devices or methods?

Leave them for us in the comments and we will answer them as soon as possible!

If you’re looking for an official quotation on the Rocket Launcher, simply request pricing by clicking on the button below.

These can easily be shipped anywhere in the world.

Note: Once you arrive at the page, scroll to the bottom 'Add to Quote'.

Our Customer Happiness Team typically responds within 6 business hours.